When developing a product, while it is extremely difficult to maintain quality of the product due to its complexity and shorter time to market, it is also important to keep the cost low to stay competitive.It becomes essential for the software developers to consider variousaspects while developing any product. Though, all the guidelines are abided, problems still arise in the software in form of defects. There are several factors for the defect to arise and product to fail such as, human factor, communication failure, poor design logic, unrealistic development timeframe, lack of skilled testing, poor coding practices etc. Besides this, the difficulty intensifies if the same defects recur during the development cycle of the products either new or enhanced versions. The solution lies in conducting the root cause analysis of the defects and then taking corrective actions so that they don’t recur.

What is Root Cause Analysis?

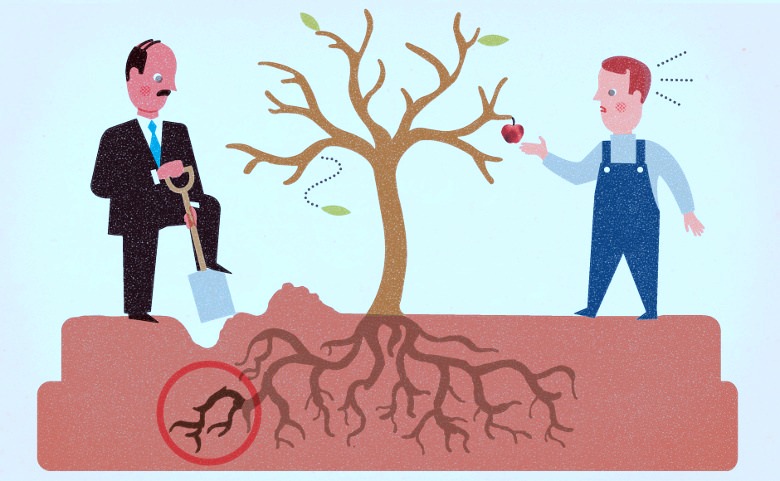

At the very basic level, root cause analysis is a methodology used to find the underlying cause of the defect. As it signifies to product development, Root cause analysis is a systematic procedure for putting the defects in categories and analysing them before release, after the release or both. WhenRCAis performed properly, it shows the points in the development cycle that are causing the main and recurring defects. Root Cause Corrective Action (RCCA) is when corrective actions are applied to solve the problems that occur during RCA. The corrective actions are carried out far upstream in the procedure as possible, as catching failures upstream prevents rework, saves time and money by not letting the problem to take place.

How it helps reduce recurring defects?

Firstly, the defects are logged and documented. Secondly, the defects are reviewed and analysed using the root cause analysis techniques. But before Root Cause analysis is performed, a Pareto graph is outlined to show the defect type with highest frequency of occurrence which becomes the target. An example of defect classification in a Pareto graph is shown below:

According to the Pareto graph, the category for which the highest numbers of defects are found should be paid attention to at first.

Defect follows the below key principles:

- Minimizing the defects to improve quality: the analysis must lead to making changes in processes which help prevention of defects in the early stages and ensure early detection.

- Utilizing local and third party expertise: the people who really know what went wrong should be there to analyse processes along with third party experts. A good debate ensures all possibilities are taken care of, analysed and the best possible action is taken.

With these guidelines, defects are analysed to find their origins. A collection of these causes will help in conducting the root cause analysis in effective manner.

Why Root Cause Analysis is extremely important?

The main benefit of RCA is that it finds the fundamental errors in the development process, enabling teams to enact right measures to fix the problems and stop them from recurring ahead. Hence, there is lesser rework and fewer defects in the final product.

- Reduced cost: the cost of fixing defects increases later the defects are found in the development process and if a defect makes it into the final release, customers may never buy the product again, resulting in loss of revenue to the firm.

- Identify failure: It points RCA is mainly helpful for teams that think they have apt development and QA procedures but still face recurring defects. Obviously, something is broken but what, why and where are the questions that need to be answered. RCA helps answer these questions and find the real (root) cause of the problem and not just the obvious (direct) cause.

- Improve safety and reliability: As root cause analysis helps reducing the number of defects in future, it can be mainly beneficial to firms in quality critical industries where product reliability and safety are mainly important.

- Enhance time to market: On finding the root cause of a defect and taking the subsequent corrective action, releases of the product take less time in testing and the product is released in the market sooner with lesser uncaught defects.

The benefits of adopting the Root Cause Analysis process to prevent defects are enormous viz. reduces development time and cost, increases customer satisfaction, reduces rework effort thereby decreases cost and improves the quality of the product.